-

PDF

- Split View

-

Views

-

Cite

Cite

Anil Haldar, Shanjitha Kantharuban, Aadhar Sharma, Jerome A. Davidson, Timothy W.R. Briggs, How to salvage a salvage endoprosthesis, Journal of Surgical Case Reports, Volume 2016, Issue 1, January 2016, rjv172, https://doi.org/10.1093/jscr/rjv172

Close - Share Icon Share

Abstract

Custom-made endoprostheses can be linked to existing well-fixed implants in the treatment of complex periprosthetic femoral fractures. By adopting this salvage approach, secure implants can be retained in favour of patients undergoing more tissue disruptive procedures such as total femoral replacements. In this piece, we present a unique case illustrating a salvage strategy for treating a failed cement-linked salvage endoprosthesis, a complex scenario which to our knowledge has never before been reported.

INTRODUCTION

Custom-made cement-linked endoprostheses can be used to salvage well-fixed implants in the treatment of complex periprosthetic femoral fractures [1–3]. To our knowledge, no cases of failed cement-linked salvage endoprostheses have been reported and we therefore present a unique case illustrating a management strategy for this challenging scenario.

CASE REPORT

A 49-year-old female with severe rheumatoid arthritis was well known to our joint reconstruction service, having undergone multiple joint replacement surgeries including shoulder, hip and knee arthroplasties. Of relevance to this case, she had a right total hip replacement and an ipsilateral distal femoral replacement.

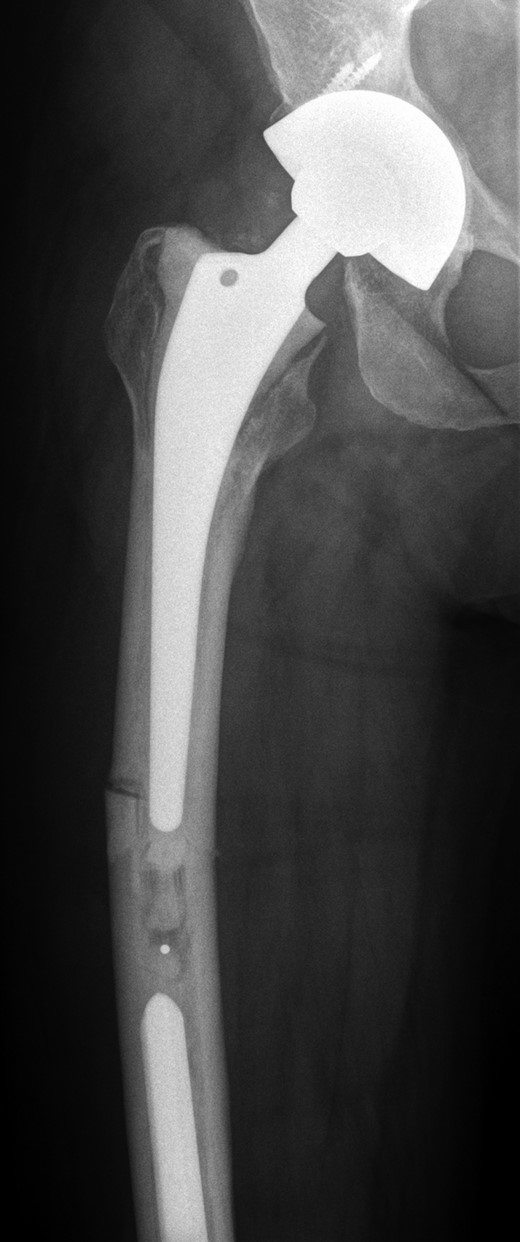

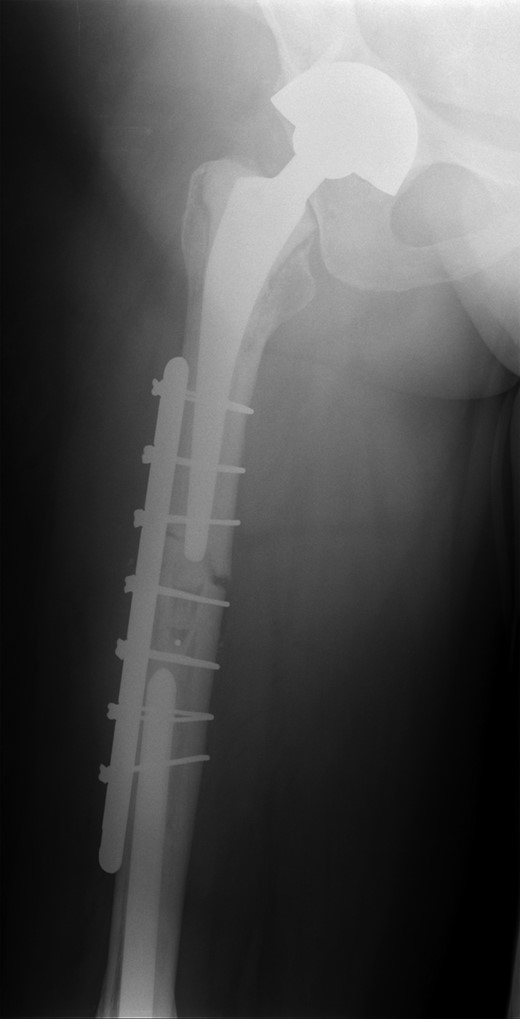

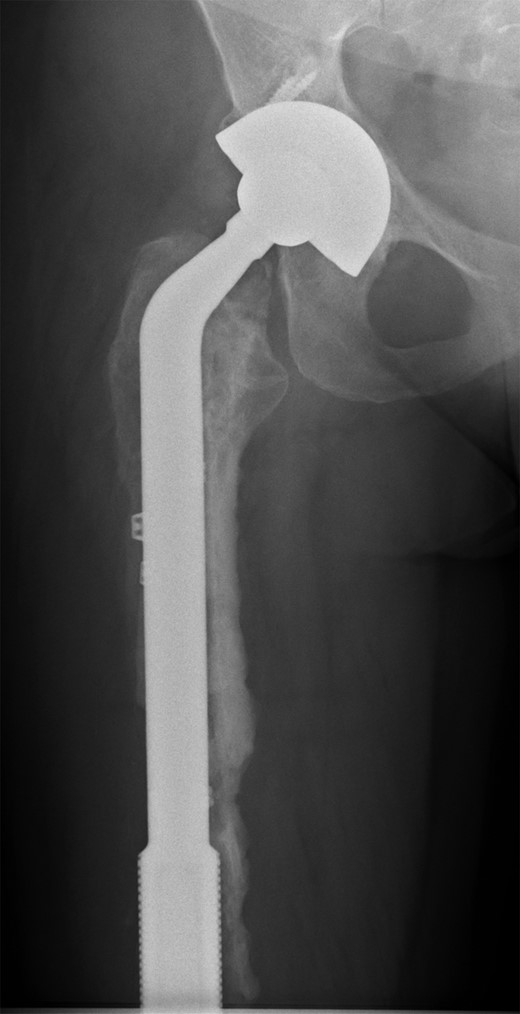

She subsequently sustained a periprosthetic fracture at the distal tip of her right total hip replacement (Fig. 1). An initial attempt was made to manage this fracture with a plate and Dall-Miles cables (Fig. 2); however, the fracture did not unite. The patient went on to have a custom-made cement-linked internal proximal femoral replacement, which had a hollow cylindrical design to accept the stem of the existing well-fixed distal femoral component (Figs 3 and 4). This linked prosthesis effectively converted her separate prostheses to a total femoral replacement, sparing her distal femoral replacement from revision. She had no problems postoperatively and recovered well from her surgery.

Periprosthetic fracture distal tip of right total hip replacement.

Plate and Dall-Miles cable fixation of periprosthetic fracture.

Custom-made cement-linked internal proximal femoral replacement.

Existing distal femoral replacement with stem linked to custom-made internal proximal femoral component visible in upper half of the image.

She remained well for 5 years, until she was referred back to our joint reconstruction unit due to a stress fracture in the stem of the distal femoral component, just below the junction with the cement-linked internal proximal femoral replacement (Fig. 5).

Full length femur radiograph illustrating fatigue fracture in stem of original distal femoral component.

After careful assessment of the radiographs and taking into consideration the complex nature of her failed salvage implant, a plan was made to design another custom-made component, this time a revision distal femoral prosthesis with a hollow cylindrical section to accept the existing, well-fixed salvage proximal femoral replacement.

The prosthesis was designed using preoperative long-leg calibrated measurement radiographs and manufactured using computer-aided design and computer-aided manufacture (CAD–CAM) techniques by Stanmore Implants Worldwide. The implant had a rotating hinge knee component and was made from a combination of hydroxyapatite-coated and silver (Agluna)-treated Cobalt–Chromium–Molybdenum (Co–Cr–Mo) and Titanium–6Alumunium–4Vanadium (Ti–6Al–4V) alloys.

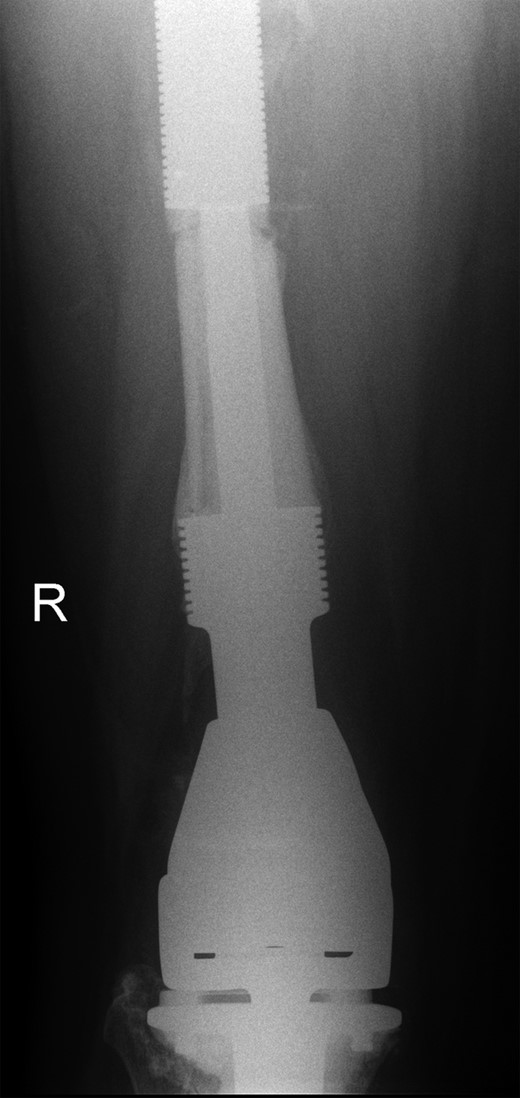

The operation was carried out by the senior author and the customized distal femoral prosthesis was successfully cemented over the pre-existing internal proximal femoral replacement (Figs 6 and 7).

Retained proximal femoral component with new custom-made cement-linked distal femoral prosthesis visible in lower half of the image.

New custom-made distal femoral prosthesis cement-linked to original salvage proximal femoral component visible in upper half of the image.

Postoperatively, the patient was advised to partially weight-bear with crutches and made a good recovery. She was discharged home 4 days post-surgery and is now 2 months post-operation. Her knee is flexing beyond 100°, which is more than she was able to achieve preoperatively and she has been cleared to fully weight-bear and return to her work as a solicitor.

DISCUSSION

We are experiencing more episodes of endoprosthetic failure [4], given the increasing use of endoprostheses in limb salvage surgery. Patients with salvage endoprostheses continue to have improved life expectancy and higher functional demands secondary to successful adjuvant therapies for tumours and infections. Therefore, these patients are living longer and their implants are more likely to fail within their lifetime, which points to a growing need for strategies to manage failed endoprostheses.

In our case, we have described a technique whereby an existing adequately fixed proximal femoral replacement was preserved with the use of a cement-linked custom-made implant. This strategy avoided a revision total femoral replacement, which allowed for less soft tissue dissection and maintenance of soft tissue attachments, all of which help to reduce morbidity and may facilitate functional recovery [1].

The concept of prosthesis salvage using custom-made linked components has been documented in previous studies. Tillman et al. [2] published a case series of custom-made prostheses with a cylindrical design cemented over existing femoral components to treat periprosthetic femoral fractures. Their rationale was to perform these operations without sacrificing ‘the good hip’ and thus avoiding the morbidity of a total femoral replacement. Five patients were included in their series and they reported no metalwork failures, dislocations, new infections or reoperations at a mean of 3.9 years.

Similarly, Peters et al. [1] described work from the USA where linked total femoral replacements were performed as implant salvage procedures to limit surgical dissection and maintain soft tissue attachments. Seven cases in this study involved a new revision stemmed distal femoral prosthesis linking to an existing hip prosthesis with a custom intramedullary sleeve. In these patients, mean postoperative Harris Hip Scores and Hospital for Special Surgery knee scores were encouraging at 72 (range 60–81) and 79 (range 64–94), respectively. There were no dislocations; however, one linked construct required a single-stage exchange of the revision total knee component for sepsis. The intramedullary sleeve and hip prosthesis were retained, and the patient is on suppressive antibiotic therapy indefinitely.

Recent work from our own centre by Patel et al. [3] illustrated the use of custom-made cement-linked megaprostheses as a salvage solution for periprosthetic femoral fractures. This study included 15 patients, 10 with retained stemmed hip implants and 5 with retained knee implants. They report favourable results, with a 93.3% implant survival rate and mean Musculoskeletal Tumour Society Score of 22.6 at a mean 5.3 year follow-up. There were no reported dislocations and one patient had a superficial wound infection, which was treated successfully with oral antibiotics.

These studies and particularly the work from our centre forged the basis of the principle we employed in our case, whereby preserving and salvaging complex endoprostheses is preferred to performing more disruptive revision surgery or even opting for amputation. However, in our case, we went a step further by salvaging a salvage custom-made cement-linked prosthesis, with a good early postoperative result. To our knowledge, this scenario has never before been reported and we believe that our technique will prove invaluable in the future, as the need to salvage failed endoprostheses grows.

CONFLICT OF INTEREST STATEMENT

None declared.