-

PDF

- Split View

-

Views

-

Cite

Cite

Nadia van den Berg, Mel Corbett, Eoin Cleere, Ivan Keogh, Instrumentation failure during microlaryngoscopy, Journal of Surgical Case Reports, Volume 2022, Issue 4, April 2022, rjac181, https://doi.org/10.1093/jscr/rjac181

Close - Share Icon Share

Abstract

Equipment failure can be a cause of morbidity during surgical procedures. We present two cases where a broken surgical instrument, a heart-shaped curved micro-grasper, colloquially termed ‘sweetheart’ micro-forceps, compromised patient safety during microlaryngoscopy. We discuss the importance of thorough safety protocols and communication between team members to mitigate this risk. Microinstruments used during microlaryngoscopy are at risk of failure or breakage due to their small size. Surgeons must be alert to the risk of equipment failure during surgery as a potential cause of patient morbidity. In our patient, loss of the broken instrument in the respiratory tract could have resulted in iatrogenic aspiration, respiratory infection and would have necessitated rigid bronchoscopy for removal. Instruments and equipment must checked and communicated by the surgical team before and after use to prevent potential patient morbidity.

INTRODUCTION

Equipment failure leads to prolonged operative time and potentially exposes patients to the need for further intervention, increasing morbidity and mortality risk. Surgical instrument failure has previously been reported in other specialities, including orthopaedics, general surgery, gynaecology as well as endodontic surgery [1–4]. Otolaryngology related faulty equipment cases, although not as commonly described, have also been noted in the literature. A case study in the UK describes the detachment and subsequent retrieval of the disposable sheath of a flexible rhinolaryngoscope inside a patient [5]. A second case describes equipment breakdown secondary to metal fatigue during a microlaryngoscopy case, resulting in aspiration of the device piece [6]. Finally, there are several case reports detailing fractured tracheostomy tubes resulting in foreign body aspiration [7–8].

CASE SERIES

We describe two cases wherein the commonly used sweetheart micro-forceps device broke intra-operatively.

The first case involved a 75-year-old female patient with a 50-pack-year smoking history, presenting with a 5-month history of hoarseness. On examination of her oral cavity and neck, no suspicious pathology was identified. Flexible nasal endoscopy revealed Reinke’s oedema. She subsequently proceeded to microlaryngoscopy. During the procedure an adrenaline pate was placed in the glottis to ensure adequate haemostasis. On removal of the pate using a sweetheart, the scrub nurse noted a missing limb of the instrument (Figs 1–3). This was immediately communicated to the surgeon. A thorough intraoperative search was conducted, including step-by-step evaluation of the operative field. Consideration was made for possible intra-operative chest X-ray and rigid bronchoscopy. Closer inspection of the operative field revealed the missing piece sitting in the sub-glottis on the endotracheal tube balloon. The broken piece was successfully retrieved without requiring further intervention.

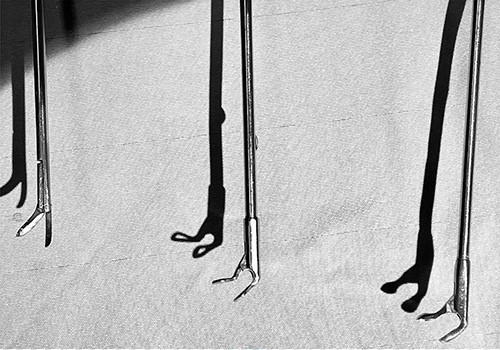

Examples of micro-forceps instruments used in microlaryngoscopy.

The heart-shaped micro-grasper as compared to an adrenaline pate.

The second case is of a 67-year-old female who underwent microlaryngoscopy to further assess and biopsy a vocal cord granuloma. During this case, the broken arm was noted by the surgeon before instrumentation of the larynx. As such, there was thankfully no consequence to the patient. Both episodes were reported as critical safety incidents during surgery to the appropriate hospital authority.

DISCUSSION

Device-related failure is seen in all surgical specialities and can have a significant impact on the success of a procedure and ultimately patient outcome. Of particular relevance to otolaryngologists is device failure within a patient’s airway. This can have catastrophic consequences, including aspiration or laryngotracheal injury. As a result of this, in such scenarios, there is added stress among team members further exacerbating an already difficult situation.

Instruments used in otolaryngology, and specifically with microlaryngoscopy, are by nature delicate in order to carry out the precision work under a microscope. The working part on these devices is only between 2 and 4 mm (Fig. 1). Their fineness increases the risk for metal fatigue and corrosion [6]. Rough handling of these intricate instruments further predisposes them to fracture. Finally, device-related failure may be due to an inherent fault during manufacturing of the device. Despite advances in medical instrument development, quality of devices produced remain as a potential area of harm. A 2006 study in the UK found that up to 15% of newly manufactured instruments, including forceps, ratcheted devices and scissors, did not meet an acceptable standard [9].

The World Health Organization safety checklist, widely implemented since 2008, has reduced patient morbidity and mortality in relation to surgical procedures by 30% [10]. Part of the checklist incorporates checking equipment with nursing staff prior to the first incision or commencement of the case. However, in the Irish adaption of the checklist, the question regarding equipment concerns is addressed to the operating team rather than the nursing staff [11]. Furthermore, the operating surgeon is ultimately responsible for knowing the working of their equipment [12]. Despite the final responsibility lying with the operating surgeon, they are often not involved in laying out the equipment, and as such, may not be aware of faulty equipment until it is handed to them, or in use.

Finally, when stress is increased in the operating room, or when things do not go as planned, it can be difficult to communicate effectively and maintain a level head. Evidence from a systematic review confirms that non-technical skills, including communication and decision-making, becomes impaired in high-stress situations [13]. Furthermore, hierarchy and organizational culture has been shown to impact the likelihood of other team members speaking up in the operating theatre in a stressful scenario [14]. This may mean someone does not speak up even if they see a device has the potential to fail! Recognition of this barrier in operating theatre is influencing surgical training, with many training bodies now requiring trainees to undergo mandatory training in open communication as well as simulation training to replicate difficult clinical scenarios. This type of communication training, based largely on ‘Crew Resource Management’, as derived from aviation training, has been shown to beneficial in team training in health care, ultimately improving patient outcomes [15].

We have instigated simple change during time-in and time-out checks during microlaryngoscopy, where the scrub nurse and surgeon check the tines of these fine instruments before and after surgical use. Central sterilization services have also been made aware of the fine nature of the tines of these instruments, requiring them to be checked for integrity before sending to the operating theatre.

Surgeons must be alert to the risk of equipment failure during surgery as a potential cause of patient morbidity. In our patient, loss of the broken instrument in the respiratory tract almost led to iatrogenic aspiration, potentially respiratory infection and would have necessitated rigid bronchoscopy for removal. The integrity of instruments and equipment must checked and communicated by the surgical team before and after use to prevent potential patient morbidity.

CONFLICT OF INTEREST STATEMENT

None declared.

CONSENT FOR PUBLICATION

Patient’s consent was obtained.